A level transmitter measures levels, right? So a hydrostatic level transmitter will definitely suit your needs, right? Unfortunately not. There are different types of level transmitters specifically designed for liquids, viscous fluids, gases, dry materials and solids, as well as contact and non-contact devices. This diversity is needed to suit different applications in different industries such as Water / Wastewater, Food & Beverage Oil & Gas Chemical and Energy; each with it’s own set of requirements, challenges and associated costs.

How Do Level Transmitters Work?

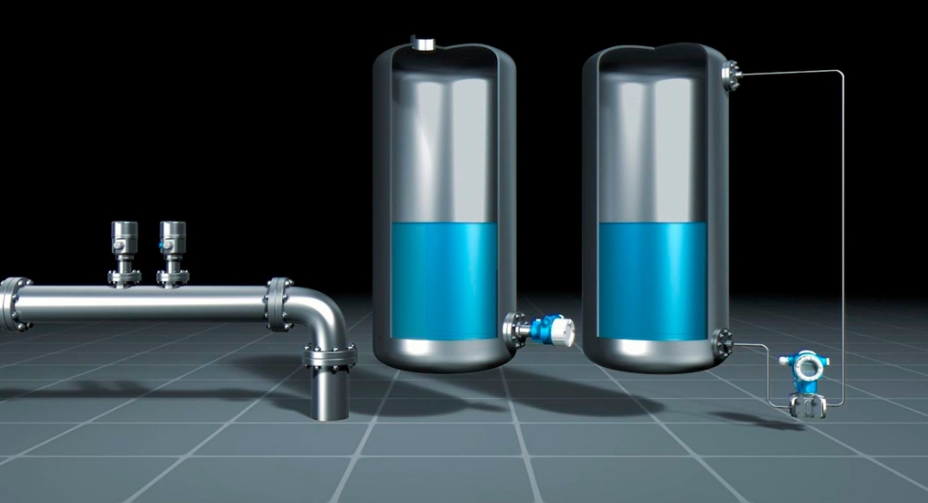

As industry needs differ, so too do the different measuring principle utilised by level transmitters. Some transmitters employ the Capacitance measuring principle, some Radar or Ultrasonic and some Hydrostatic. But all have a similar goal; to accurately, reliably and cost-effectively measure the levels in tanks, silos and sumps.

The Different Types Of Level Transmitters Available

Some of the main continuous level transmitters available are as follows:

Capacitance Level Transmitter – A probe is placed in a vat (or similar) of liquid (the dielectric medium). The higher the liquid level, the greater the capacitance. This method is ideal for small vessels with rapidly changing levels.

Hydrostatic Level Transmitter – These are pressure level transmitters which determine the mass of the liquid present in a vat (or similar) by measuring the force exerted on the measuring diaphragm. This provides a cost effective solution for sanitary applications or in sumps via the an extended probe and cable version.

Magnetic Level Transmitter – Usually only used nowadays as a visual indication of what is inside a vessel. This uses magnetism to link the indicator in a gauge to a float inside of a vessel in order to accurately show the level of fluid within. Being a mechanical system, it makes this measurement method not as reliable as those with no moving parts.

Radar Level Transmitter – Also known as Microwave Level Measurement, this is the emission of radio waves from the top of a tank (or similar) into the target liquid or solid. The waves a reflected back when they see a change in dielectric. The transmitter measures the time taken to send and receive these waves and then calculates the level. Ideal for non-contact measurement in small and large vessels.

Ultrasonic Level Transmitter – Similar to Radar but in this case emitting sound waves as ultrasonic pulses, which reflect from the surface due to the change in density. Based on the speed of the reflection, the transmitter determines the level. Although not as popular as it used to be due to the introduction of Radar technology, Ultrasonic transmitters still have their place, especially measuring the level of coarse bulk solids.

Guided Microwave Level Transmitter – A sensor emits microwave pulses down a cable or rod. The reflected waves are recorded by the sensor and processed by the transmitter to calculate the level data. The speed of reflection is again used. As the signal is ‘guided’ this method has proven to be very reliable especially in fine and dusty bulk solids.

So, Hydrostatic level transmitters certainly have their place in the level line-up but are certainly not the solution for every application across every industry. At EMC we offer the widest range of level transmitters in New Zealand to ensure we provide you with precise, fast and reliable measurement to enable you to manage the levels of all products in vats, tanks, containers or dams.

We’ve been measuring New Zealand for fifty years! Ask us if a quality hydrostatic level transmitter is right for you.