Loss in Weight Controllers, or Loss in Weight Feeders, are often the desired measurement system for bulk solids as they can be used for a wide variety of different applications due to their highly regarded accuracy. In fact, they are looked upon as the most accurate of all continuous weighing devices on the market, and prove to be absolutely essential in situations in which precision is necessary.

Loss in weight controllers can be used to achieve accurate control for blending, managing the feed rate of minor additives, and for materials with low throughputs. They can also increase efficiency by optimising the bulk flowrate of products into say a dryer or salt into a cheese salting system. There are various other applications for this type of equipment and that’s why they are found in production factories worldwide.

How Does it Work?

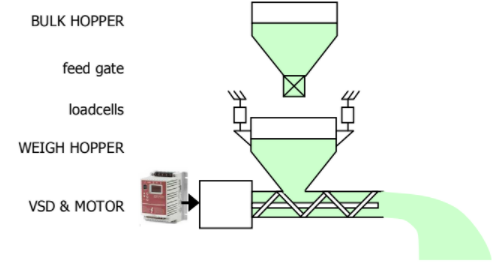

The principle of how Loss in Weight (also known as Weight Change) Controllers work is actually quite simple. Loadcells are wired to the controller which in turn measures the amount (mass) of product in the weigh hopper. The controller then controls the motor speed on a flow regular via a variable speed drive (VSD) to achieve the desired flowrate. Common flow regulators used for these systems are augers or rotary valves. The controller is also used to send a signal to fill the weigh hopper from the bulk hopper before it empties which keeps the process continuously running.

What Are Some of the Benefits?

The metering of bulk solids is not as easy as with say a liquid. So there are reasons why Loss in Weight Controllers are so popular to control the flow of bulk solids. Some of their benefits include:

High Accuracy:

When a Loss in Weight Controller is being operated as it should, you can expect levels of ± 0.25% or better accuracy. It is this accuracy that makes these forms of equipment essential to many projects.

Effective Flow Rate Control:

Another advantage is that very low flow rates can be achieved in a suitably designed system to properly handle the product effectively (eg. Additives)!

Features of Your Average Loss in Weight Control System

Each Loss in Weight control system may be slightly different and subject to different characteristics due to the product to be measured and the flowrate required. Feeders can either be screw fed, belt fed, rotary valve fed or rotary table fed, which come in various sizes and materials.

Most Loss in Weight Control Systems include the following:

- Variable Frequency Drive

- Motor

- Load Cells

- Weigh Hopper

- Refill Device

- Feed Device

- Loss in Weight Controller

With so many advantages, and easy application, it is no wonder that these devices have gained such popularity and acclaim.

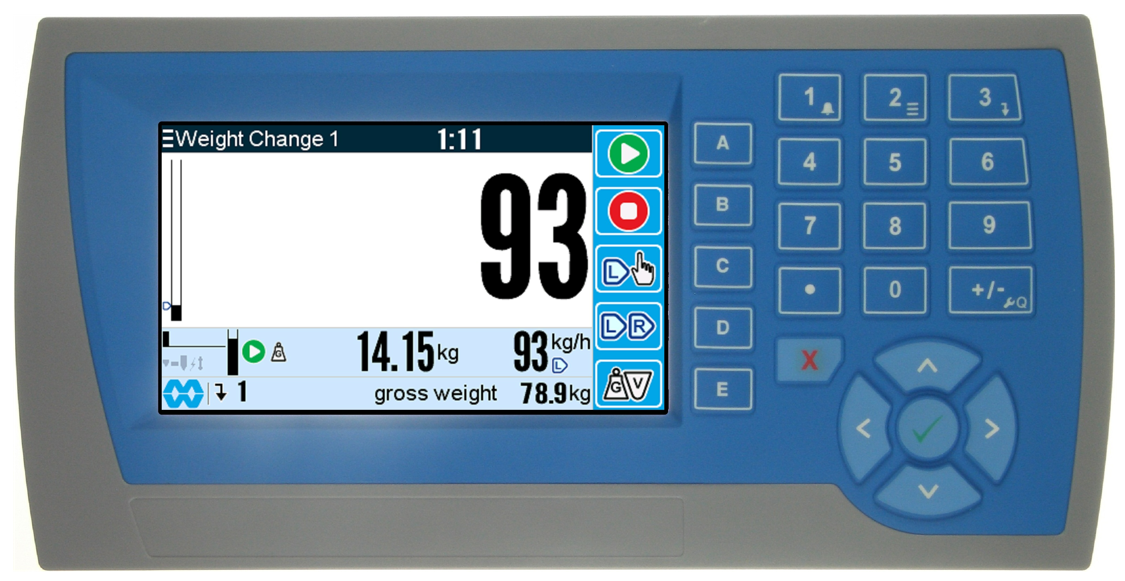

Are you looking to purchase a loss in weight controller in NZ? Here at EMC, we manufacture our own brand of ‘ModWeigh’ weighing processors, including the MW93A loss in weight controller, and can design and manufacture a complete loss in weight system to suit your exact needs. Contact us for further information should you require it on 09 415 5110 or sales@emc.co.nz.