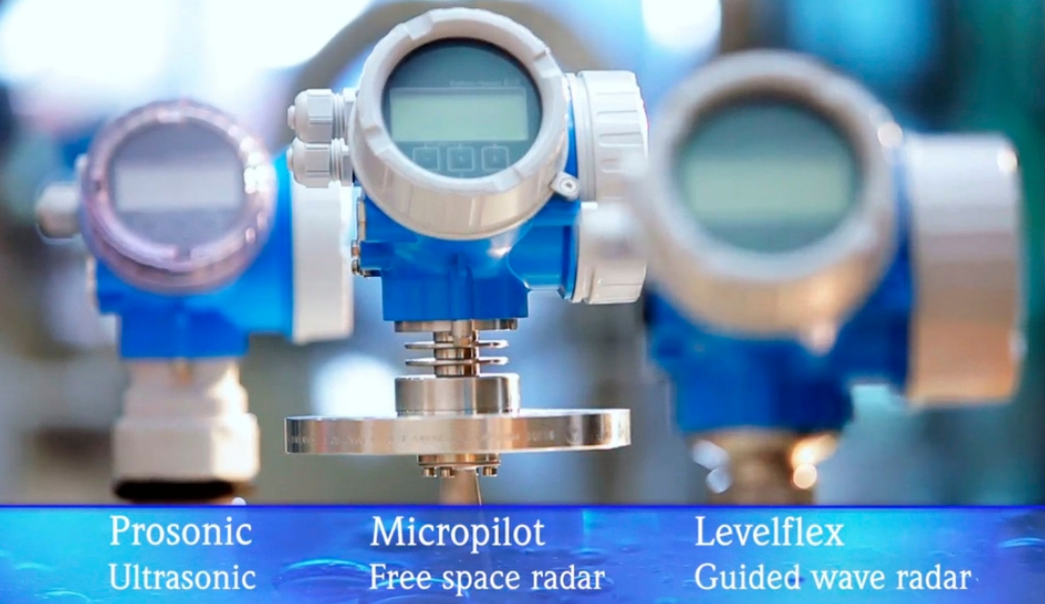

Both Radar and Ultrasonic level transmitters are in common use for measurement of level in all sorts of industries – Water Treatment, Wastewater, Primaries, Chemical, Food & Beverage, Oil & Gas. In this article we’ll be comparing two types of non-contact “time-of-flight” level measurement instruments – Radar level transmitters and Ultrasonic level transmitters. We will be pointing out the advantages and thereby the limitations of each to help you determine the right choice for your needs.

For starters, the right choice (ie. which technology to apply) depends largely on the application itself. What is the product to be measured, what is the measuring range required, what is the operating temperature and pressure, what accuracy is required etc. and also importantly, what is the most cost effective solution?

So let’s take a look at some of the advantages and typical applications of each measurement technology.

Advantages of Radar level transmitters

- Virtually no influence from the airspace above the medium (Temperature, Pressure, Vacuum, Gas layers, Dust)

- Suitable for a wide range of process temperatures and pressure, including full vacuum

- Various frequencies available to suit different applications

- Very narrow beams are possible depending on frequency and antenna

- High accuracy

- Small process connections are possible

- Very large measuring ranges

- Low power (independent of measuring range)

- Well suited to Ex hazardous areas due to 2-wire technology

Typical Applications for Radar level transmitters

- Water reservoirs

- River and lake levels

- Water/wastewater pumping stations

- Wastewater ponds

- Aggregates and powders in quarry and mining plants

- Chemical tanks (including IBC’s)

- Drilling mud and chemicals in Oil & Gas

- Tank Farms in all industries

Advantages of Ultrasonic level transmitters

- Unaffected by medium Dielectric

- Self-cleaning membrane (Dust and Condensation)

- Sharp signals good for short ranges (open channel flow)

- Separated versions available (sensor/transmitter)

Typical Applications for Ultrasonic level transmitters

- Water reservoirs

- Open channel flow in water/wastewater and irrigation

- Aggregates in quarry and mining plants

- Low dielectric media in Food & Beverage such as chocolate

To learn more about ‘time-of-flight” instruments and how the Ultrasonic measuring principle differs from Radar take a look at the following:

At EMC we don’t apply a one size fits all approach to level measurement when selecting a level measurement transmitter as there are definite advantages and disadvantages for each measurement technology.

Are you looking to purchase a level transmitter in New Zealand? At EMC Industrial Group we have the widest range of level measuring instruments available; all from our main supplier, Endress+Hauser. Let us know your applications details and requirements and we’ll help you select the level measurement device that best suited to your needs.